One Revolution Per Day

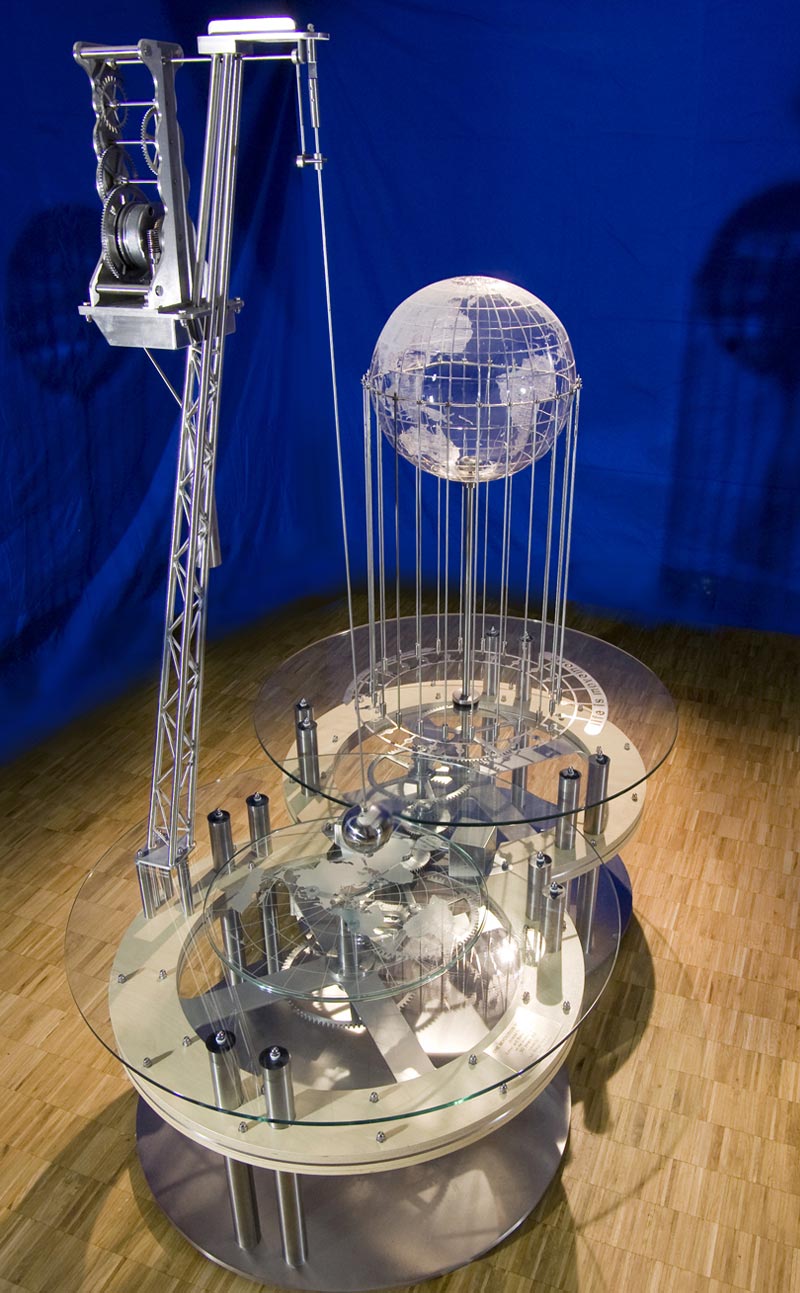

Commissioned by Robert and Esther Mathys and presented to the AO Foundation on the occasion of their 50 year jubilee celebration.

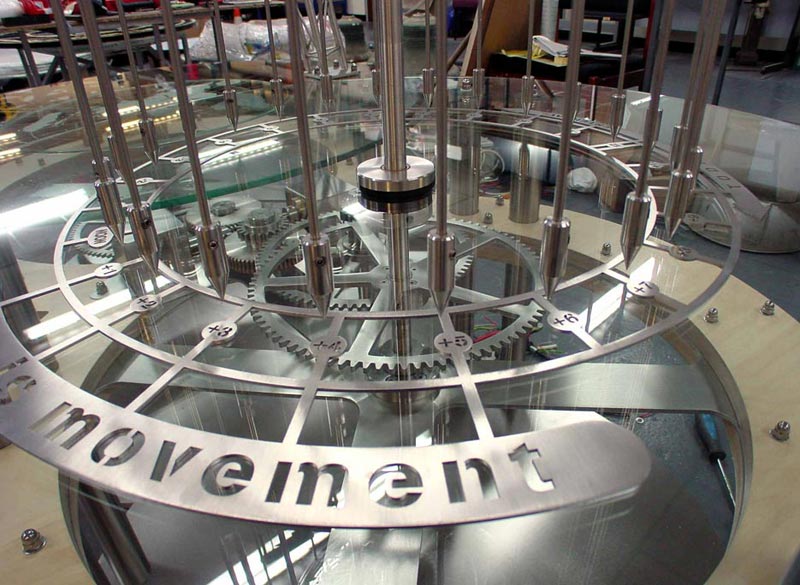

Stainless steel longitude indicators hang from the globe's equator. These points in conjunction with the time zone calibration ring offer the correct time anywhere on earth.

The clockworks to drive “One Revolution Per Day” are built by Smith of Derby, U.K.

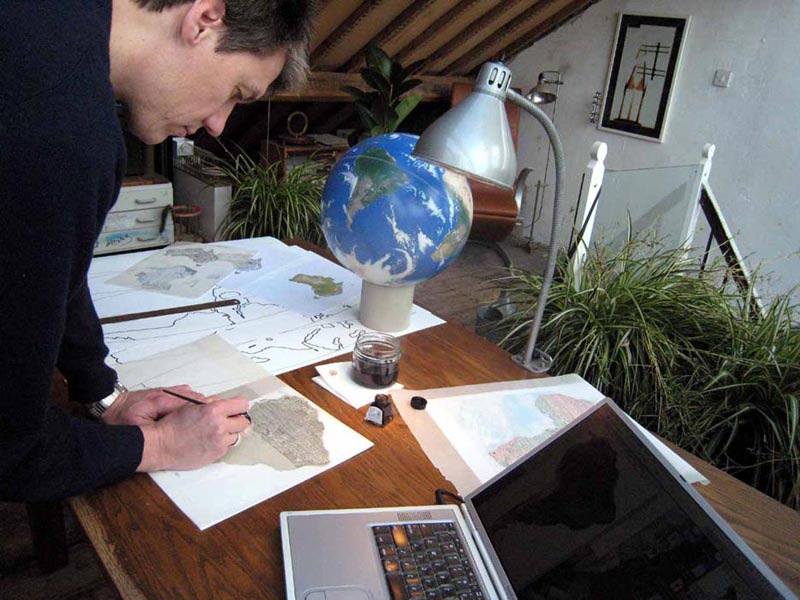

An initial concept drawing arrives after exploring several possible formats that range dramatically in scale and location.

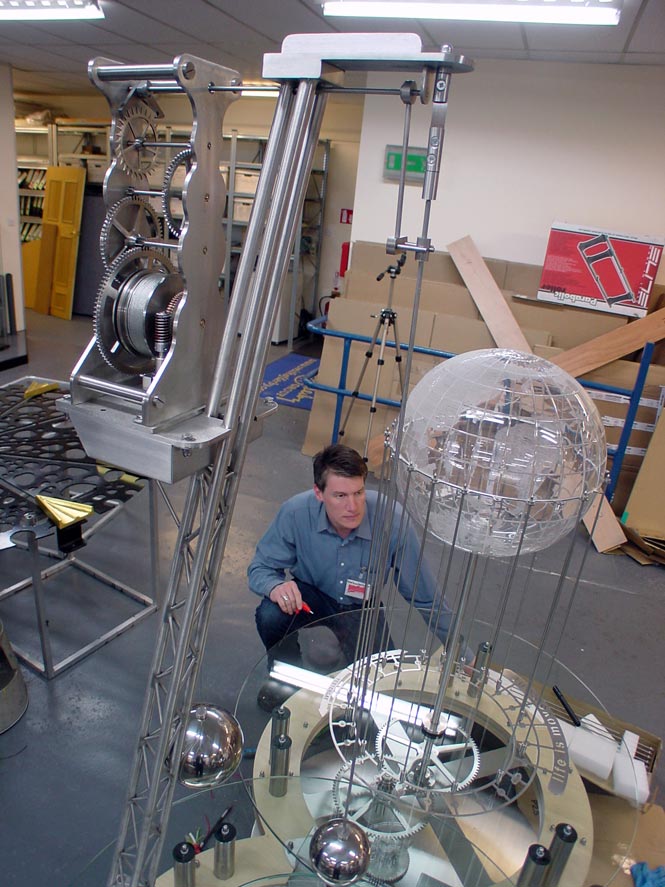

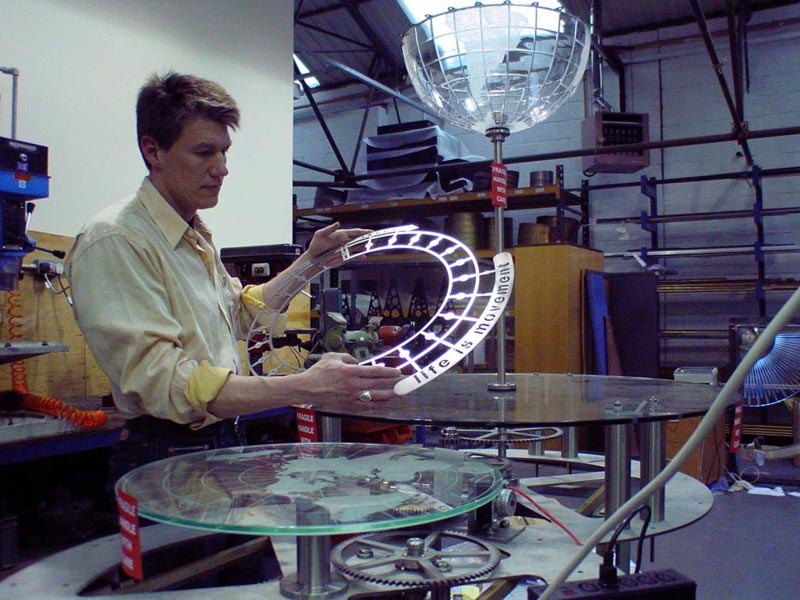

Once a concept is chosen, a maquette is built to test materials and fabrication options.

All crystal is hand blown. A perfect hemisphere is carved into a solid block of wood to "true" the blown glass while it is still molten.

The globe of "One Revolution Per Day" is 18 inches in diameter, the largest sphere Tyrone crystal ever produced.

With great care Owen McKee, the master blower, blows two hemispheres for making the globe.

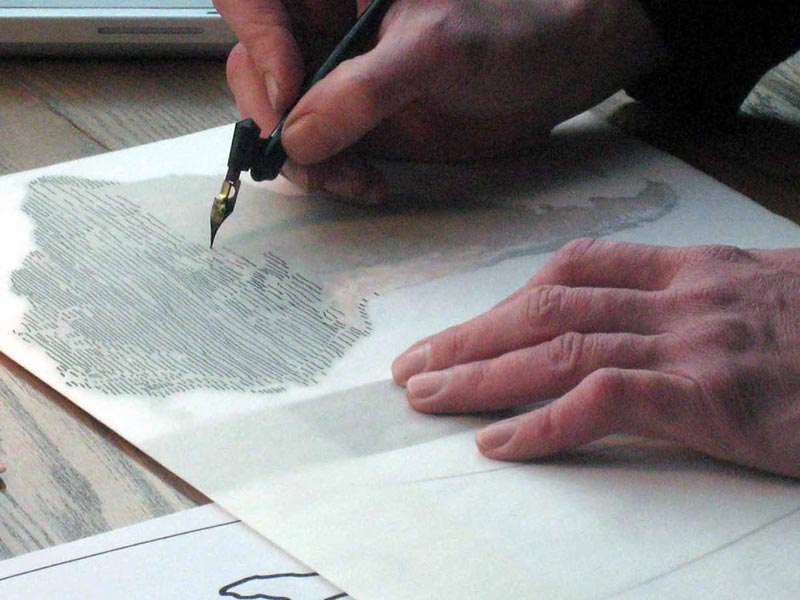

The next job is to create the textured pattern that is carved into the glass to indicate continents and their topography.

Influenced by the line work of Durer's etchings, a drawing for each continent is created and carved onto the globe.

A unique crystal globe with stainless steel equator ring.

All components are collected at the Smith of Derby factory for assembly.

The quality of workmanship offered by the engineers and craftsmen at Smith of Derby is excellent. This is a world-class operation.

Documentation & Media

- [x] All

- [x] Commissioned

- [x] Gallery

- [x] Interiors